NEWS

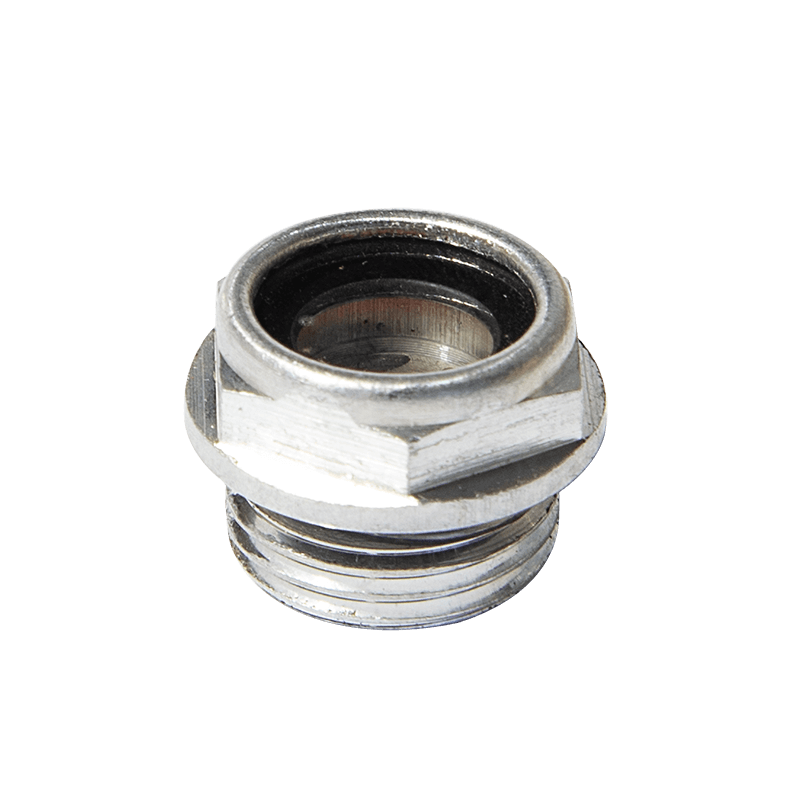

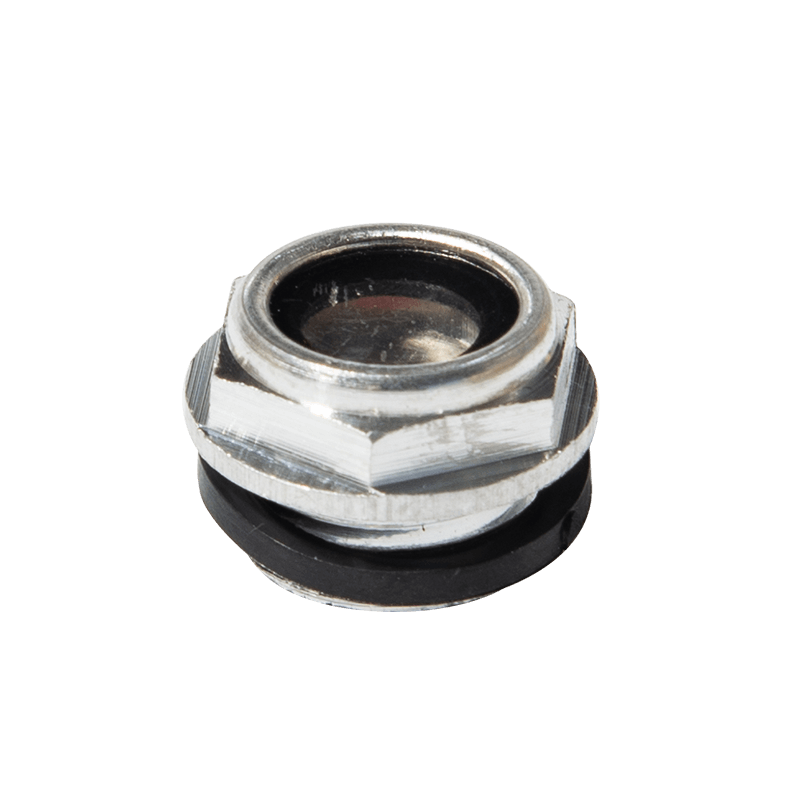

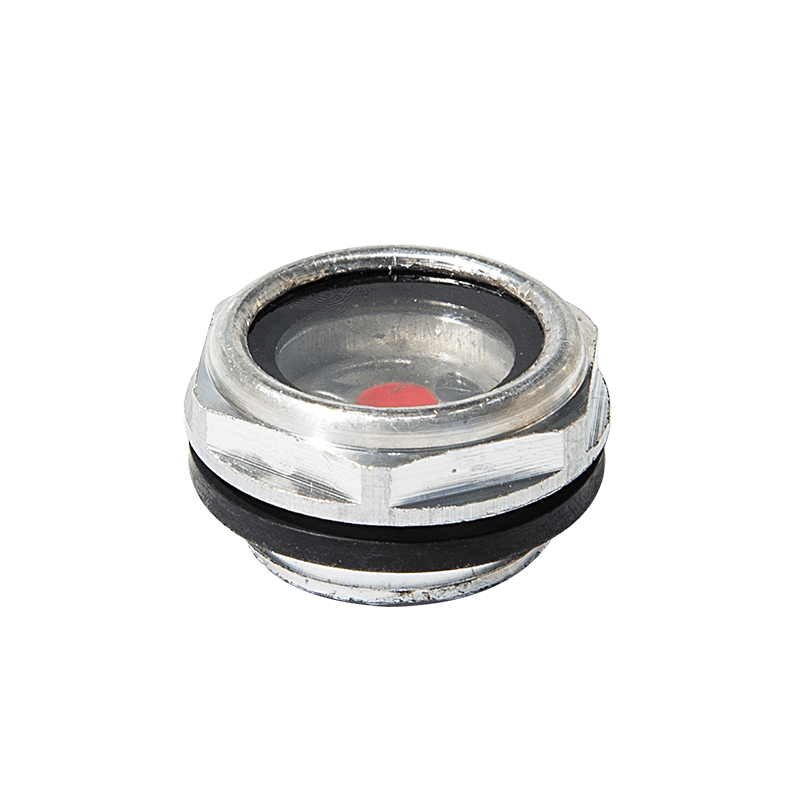

How to perform surface treatment to improve the wear resistance and aesthetics of Aluminum Oil Level Sight Glass?

Anodizing:

A layer of aluminum oxide film is formed on the aluminum surface through an electrochemical process. This film not only enhances wear resistance, but also provides good corrosion resistance and oxidation resistance. Anodizing can also provide a variety of color options to improve aesthetics.

Spraying:

Spraying the aluminum surface with powder coating or liquid coating to form a protective film. Spraying not only increases wear resistance, but also provides different colors and glossiness according to needs.

Polishing:

Mechanical polishing of the aluminum surface can remove surface defects and make it smoother and more beautiful. The polished surface is more shiny and can also improve a certain wear resistance.

Cleaning and decontamination treatment:

During the processing process, the aluminum is cleaned to remove oil and impurities, which helps the adhesion of subsequent surface treatment and improves durability.

Sandblasting:

Through the sandblasting process, a certain degree of roughness can be created on the aluminum surface, increasing the adhesion of the coating and improving the appearance.

Sealing treatment:

Sealing treatment after anodizing can further enhance wear resistance and corrosion resistance and prevent wear and discoloration of the aluminum oxide film.

Electrophoretic coating:

The electrophoretic coating technology can form a uniform coating, improve wear resistance, corrosion resistance and aesthetics, and achieve coating of complex shapes.

Related Products

Categories

Recent Posts

Contact Us

Our company was founded in 2004, the company set research and development, production, sales in one, deep cultivation reducer/air compressor/and other industries for more than 20 years.

- +Home

- +News

- +Products

- +About Us

- +Contact Us

-

+86-13758584936

-

+86-0575-87697712

-

+86-0575-87697712

-

-

No.458, Qingshanling Village, Diankou Town, Zhuji City, Zhejiang Province, China

Contact Us