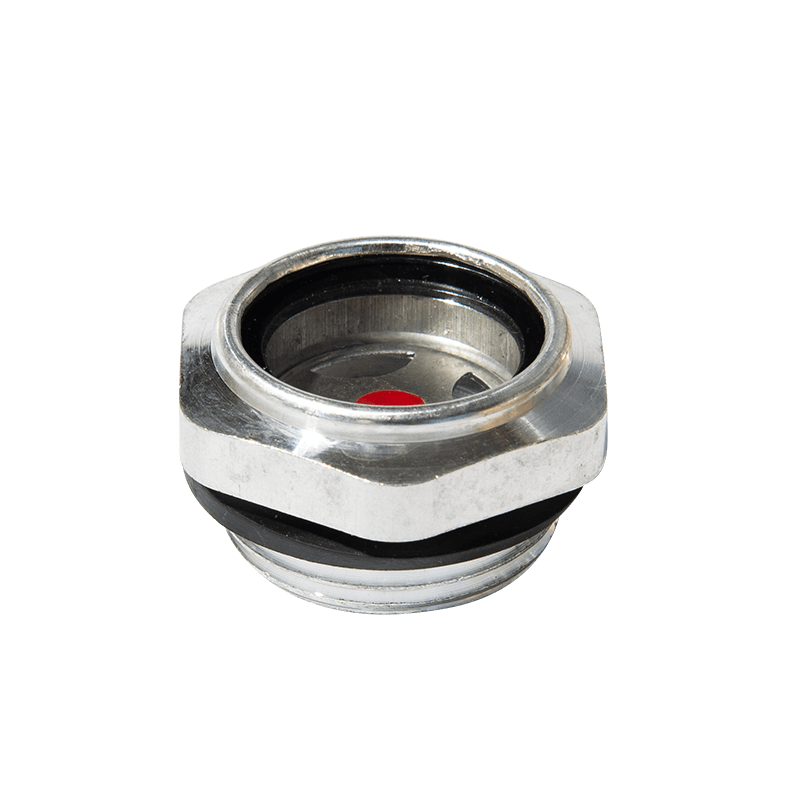

If the oil level is lower than the lower line marked on the oil level sight glass for a long time, what impact will it have on the machinery?

When the oil level is lower than the lower line marked on the oil level sight glass for a long time, the impact on the machinery is multifaceted. Motor oil reduces direct contact between metal parts, thereby reducing friction and wear. When the oil volume is lower than the lower line marked on the oil level sight glass for a long time, the lubrication effect will be significantly reduced. The lack of sufficient oil film between metal parts will lead to dry friction or boundary friction, which not only accelerates the wear of the parts, but may also cause vibration and noise, reducing the operating efficiency of the equipment.

Another important function of engine oil is cooling. It can take away the heat generated during the operation of mechanical equipment through circulation, ensuring that the equipment operates within the normal operating temperature range. Insufficient oil will limit the cooling capacity of the engine oil, causing the machine to overheat. This will not only further increase the wear of parts, but may also affect the performance and reliability of the equipment, and even lead to serious consequences such as thermal stress cracks or deformation.

Prolonged engine oil starvation significantly increases the risk of mechanical failure. Without adequate lubrication and cooling, mechanical equipment parts can be subject to severe wear, overheating, and corrosion. These damages can lead to component failure, such as bearing damage, piston ring breakage, gear wear, etc. In addition, overheating may also cause the engine oil to deteriorate and form sludge and deposits, further deteriorating the lubrication effect and accelerating the damage of parts.

The reduction of engine oil not only affects the lubrication and cooling effects, but may also affect the overall performance of the mechanical equipment. For example, insufficient engine oil may result in reduced engine power, slow acceleration, and increased fuel consumption. In the hydraulic system, insufficient oil will lead to insufficient pressure, affecting the stability and control accuracy of the system.

Prolonged lack of engine oil will accelerate the aging and damage of mechanical equipment, thereby shortening its service life. Not only does this increase the cost of repairs and replacement parts, it can also affect the reliability and safety of the equipment. In some cases, insufficient engine oil may even lead to catastrophic failure of the equipment, causing serious economic losses and personal injury.

Modern machinery and equipment are often equipped with oil level alarm systems to monitor the level of engine oil. When the oil level falls below a certain level, the alarm light will light up to remind the operator to replenish the engine oil in time. However, if the operator ignores this warning, the best opportunity for repair may be missed, causing the failure to escalate. Not only does this increase the difficulty and cost of repairs, it may also have a long-term negative impact on the performance and reliability of the equipment.

If the oil level is lower than the lower line marked on the oil level sight glass for a long time, it will have a serious negative impact on the mechanical equipment. In order to ensure the normal operation of mechanical equipment and extend its service life, operators should regularly check the oil level sight glass to ensure that the oil level is always maintained between the upper and lower lines marked. Once the oil level is found to be lower than the lower line, the engine oil should be replenished immediately and checked for potential problems such as oil leakage. At the same time, operators should also strengthen the maintenance and upkeep of mechanical equipment to ensure its long-term stable operation.

Contact Us