Is the oil drain plug suitable for hydraulic machinery such as diesel engines?

The oil drain plug, as an indispensable component in the hydraulic system, has the main function of facilitating the discharge, replacement or inspection of the oil in the system when necessary. In complex hydraulic machinery such as diesel engines, the importance of the oil drain plug is particularly prominent. It not only simplifies maintenance work, but also ensures the cleanliness and operating efficiency of the system.

During the operation of the diesel engine, the engine oil will gradually age or become contaminated over time. Regular oil replacement is the key to maintaining stable performance and extending the service life of the diesel engine. At this time, the oil drain plug plays a vital role, allowing technicians to easily open and drain the old oil, and provide convenience for the addition of new oil.

In addition to oil replacement, diesel engines may also require other maintenance work during long-term use, such as cleaning the oil channel and replacing the filter. In these maintenance processes, the oil drain plug also plays a key role. It allows technicians to easily discharge the residual oil in the system and ensure the smooth progress of maintenance work.

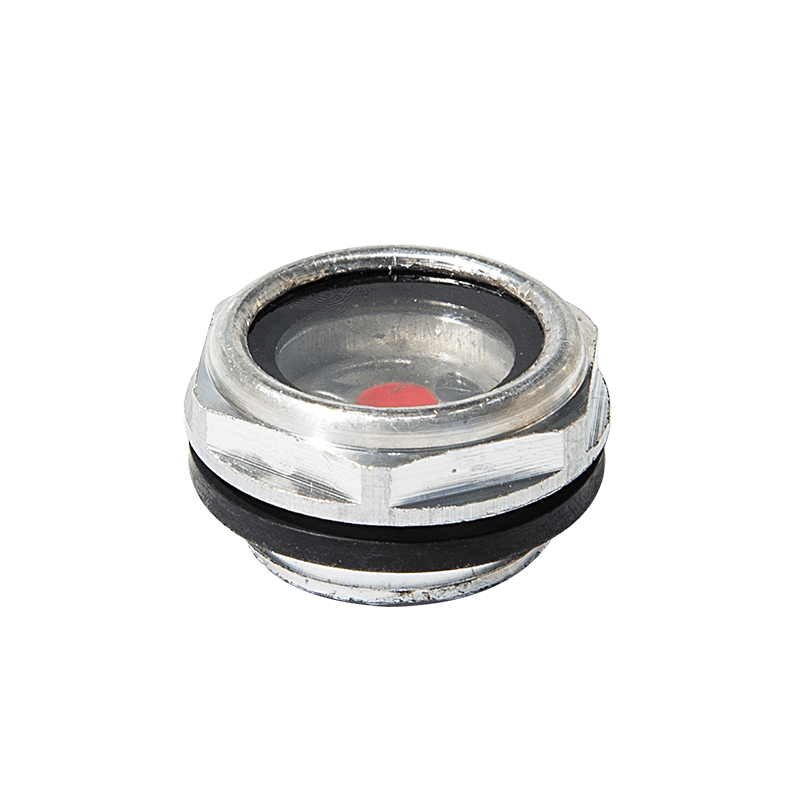

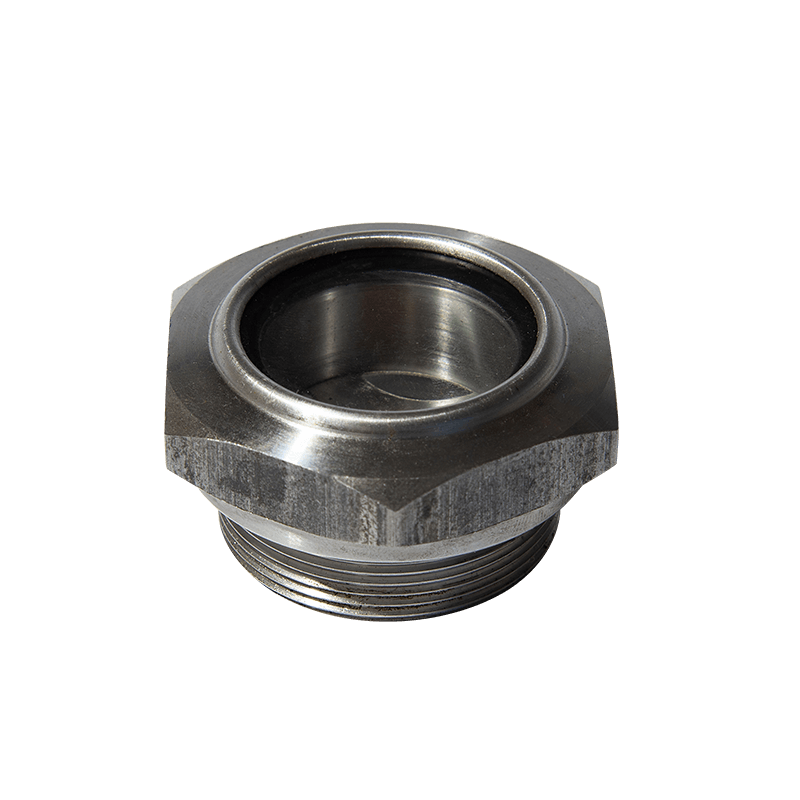

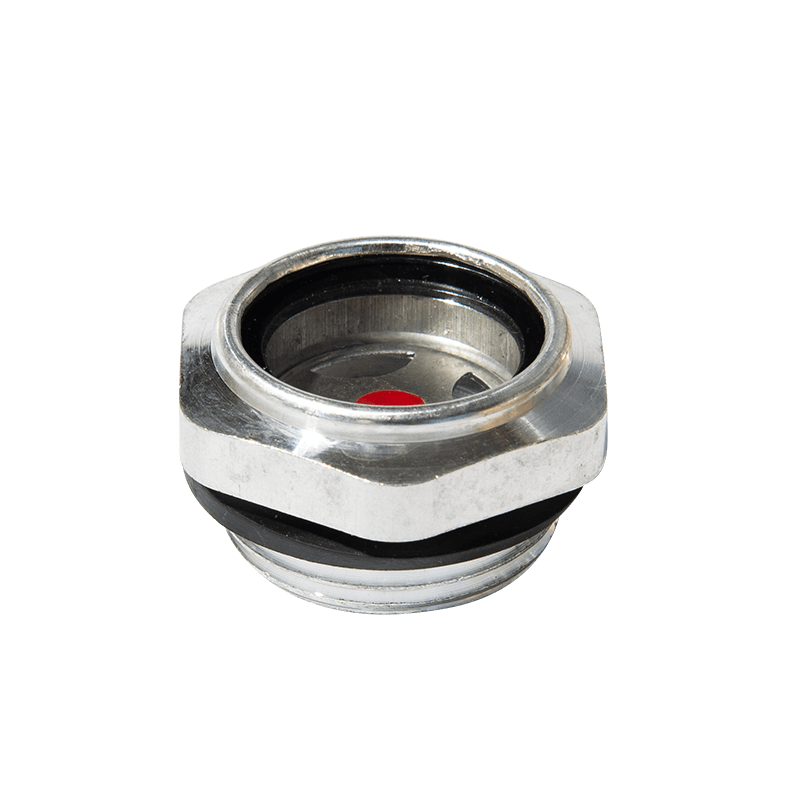

The sealing performance of the oil drain plug is crucial. During the operation of the diesel engine, if the oil drain plug leaks, it will not only cause a waste of oil, but also may affect the normal operation and stable performance of the diesel engine. Therefore, high-quality drain plugs are usually made of precise processing technology and high-quality materials to ensure that they have good sealing performance.

In order to meet the needs of different diesel engines, the production materials of drain plugs are also diverse. High-quality carbon steel, alloy steel, and stainless steel materials such as 304, 316, and 410 are widely used in the production of drain plugs. The selection of these materials is intended to improve the corrosion resistance, wear resistance, and high temperature resistance of the drain plugs. In addition, the drain plugs also follow domestic and international standards such as GB, JIS, BS, DIN, ANSI, NF, JB, JQ, JQ/ZQ. These standards not only ensure that the quality and performance of the drain plugs meet international standards, but also provide a reliable reference for technicians in the process of purchase and use.

When purchasing the drain plug, it should be selected according to factors such as the model, specification, and operating environment of the diesel engine. At the same time, attention should also be paid to key indicators such as the material, sealing performance, and service life of the drain plug. It is recommended to give priority to brands and products with good reputation and reputation. Regular inspection and maintenance of the drain plug is the key to ensure its normal operation. During use, if the drain plug is found to be leaking, loose or damaged, it should be replaced or repaired in time. In addition, care should be taken to keep the drain plug clean and dry to avoid corrosion and blockage.

Contact Us