What are the advantages of Brass Breather Valve compared to other materials?

As a copper-zinc alloy, the material of Brass Breather Valve has natural corrosion resistance, especially in terms of atmospheric corrosion, fresh water corrosion and corrosion of certain chemical media. This feature enables Brass Breather Valve to maintain a stable working state in a variety of harsh environments, extending the service life of the equipment. In addition, brass also has good wear resistance, which reduces the wear of the valve body caused by frequent switching or medium flow, and further improves the durability of the valve.

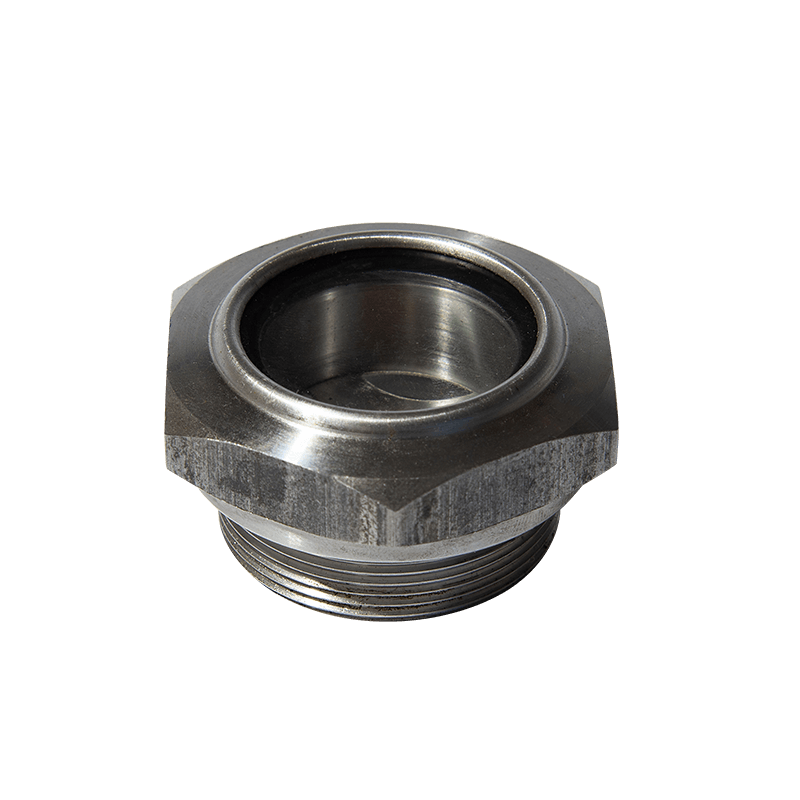

Brass has excellent casting performance and can easily realize the design and production of complex structures, which is especially important for products such as breathing valves with fine internal structures and high sealing requirements. At the same time, the plasticity and ductility of brass make it easy to process into various shapes and sizes to meet different application requirements. This flexibility not only improves production efficiency, but also reduces customization costs.

Brass has excellent thermal conductivity, which means that in an environment with large temperature changes, Brass Breather Valve can reach thermal equilibrium faster and reduce the problem of sealing failure caused by thermal expansion and contraction. In addition, brass has good thermal stability and can withstand high temperatures within a certain range without deformation. It is suitable for high-temperature media treatment in industries such as petrochemicals and chemicals.

Due to its material properties, brass breather valves can adapt to a variety of media environments, including corrosive media, high-pressure media, and high-temperature media, so they are widely used in many fields such as petrochemicals, pharmaceuticals, food, and water treatment. Its good compatibility makes brass breather valves an ideal choice for solving specific industrial needs.

Although the initial cost of brass materials may be higher than some common metals, considering its long-term durability, easy maintenance and replacement advantages, the total cost of ownership of brass breather valves is actually lower. In addition, as a recyclable material, brass is in line with environmental protection trends and helps reduce the environmental impact costs of enterprises. Therefore, in the long run, brass breather valves have a high cost-effectiveness.

Brass is a recyclable material, and the waste generated during its production process can be recycled and re-refined, reducing dependence on primary resources. With the increasing global awareness of environmental protection, products made of sustainable materials such as brass are increasingly favored by the market. Brass breather valves not only meet the needs of industrial applications, but also conform to the concept of green manufacturing and promote the development of a circular economy.

Contact Us